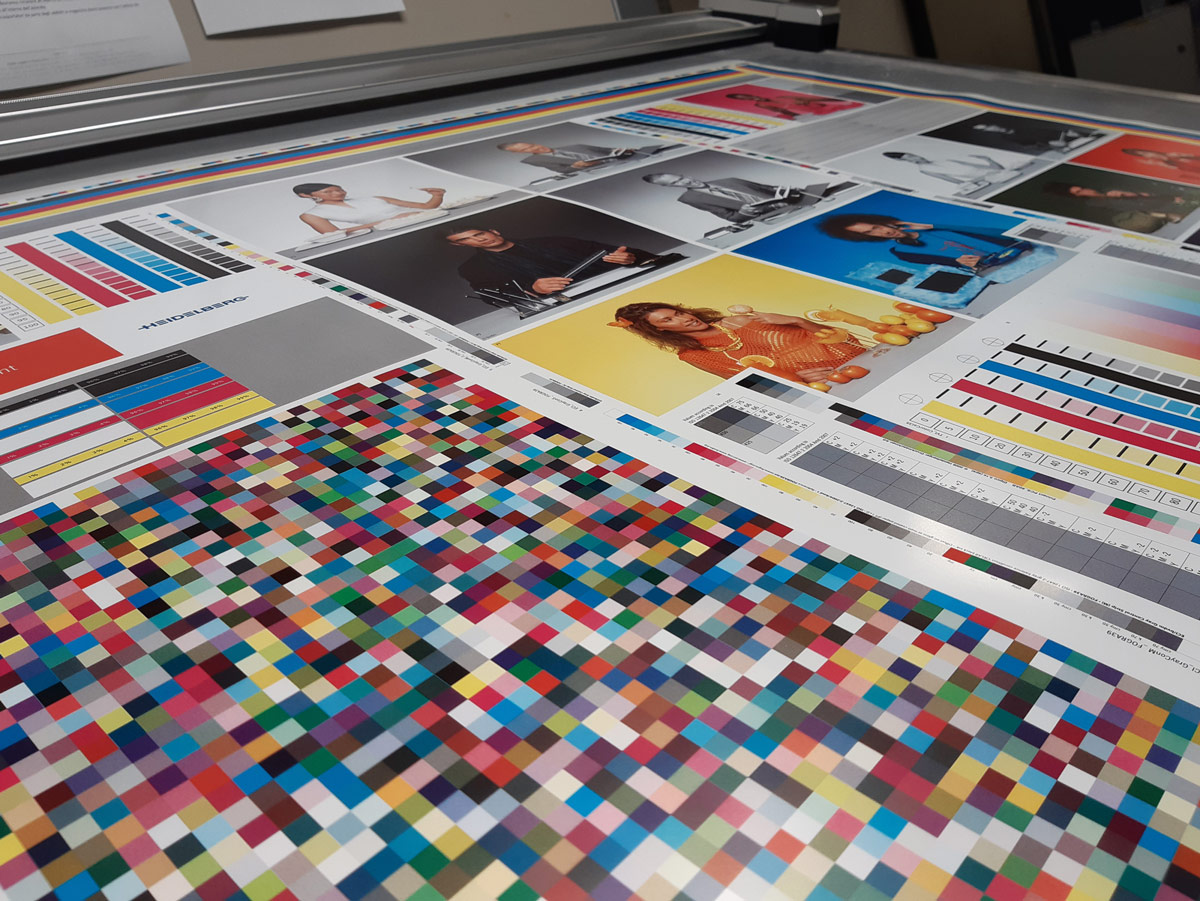

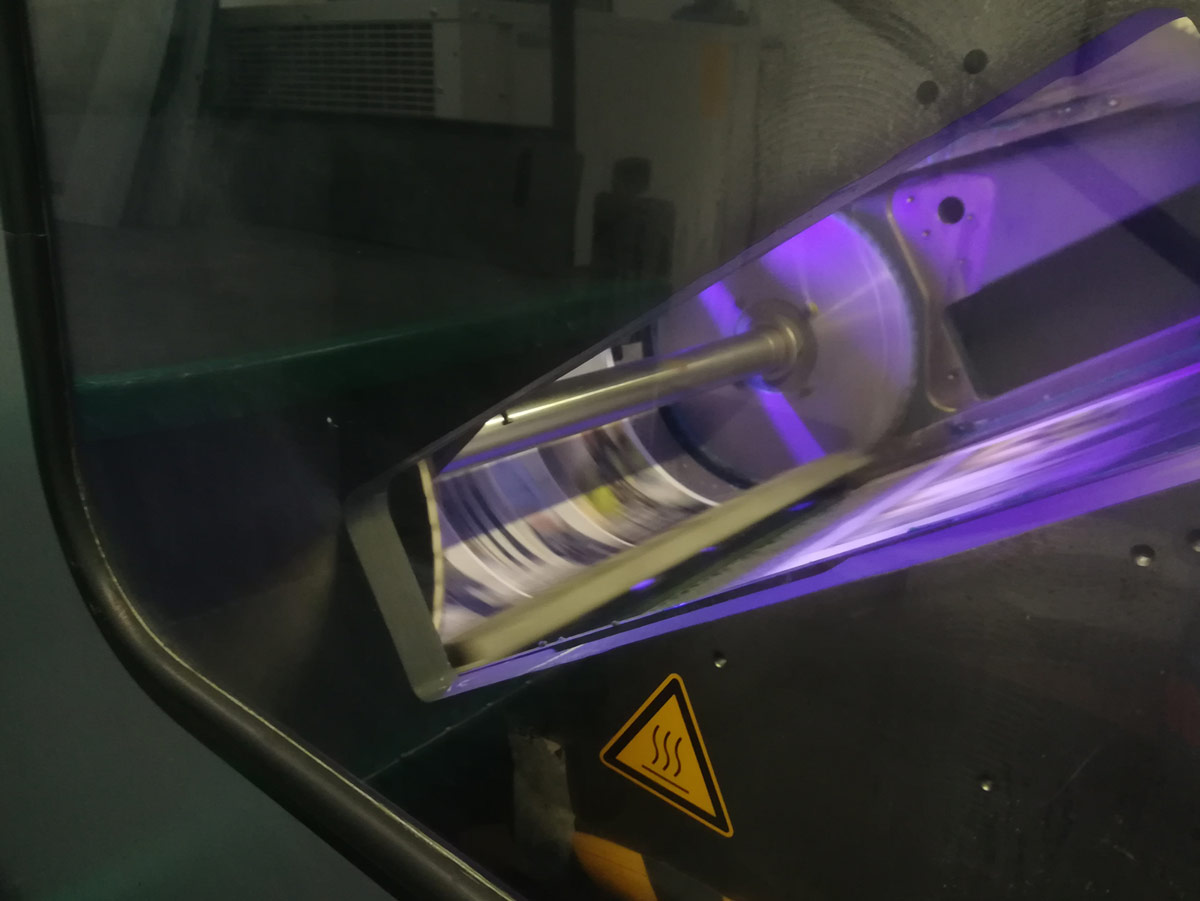

The economic advantages of introducing PrintLED technology in lithography on tinplate, aluminium, steel are now well established.

Possibility of expanding the range of substrates to print on, even the most difficult ones. We boast a great number of retrofit installations on Top Brand presses.

The wide variety of problems of screen printing finds a great ally in PrintLED UV LED systems with a more sustainable approach.

PrintLED curing systems are specially designed for the best results with UV LED inks and varnishes for digital, with proven effectiveness on many types of substrates (metal, plastic, paper, cardboard, wood, etc).

The company’s experience with large-format dryers is also easily applied to smaller sizes, typical of narrow web presses.

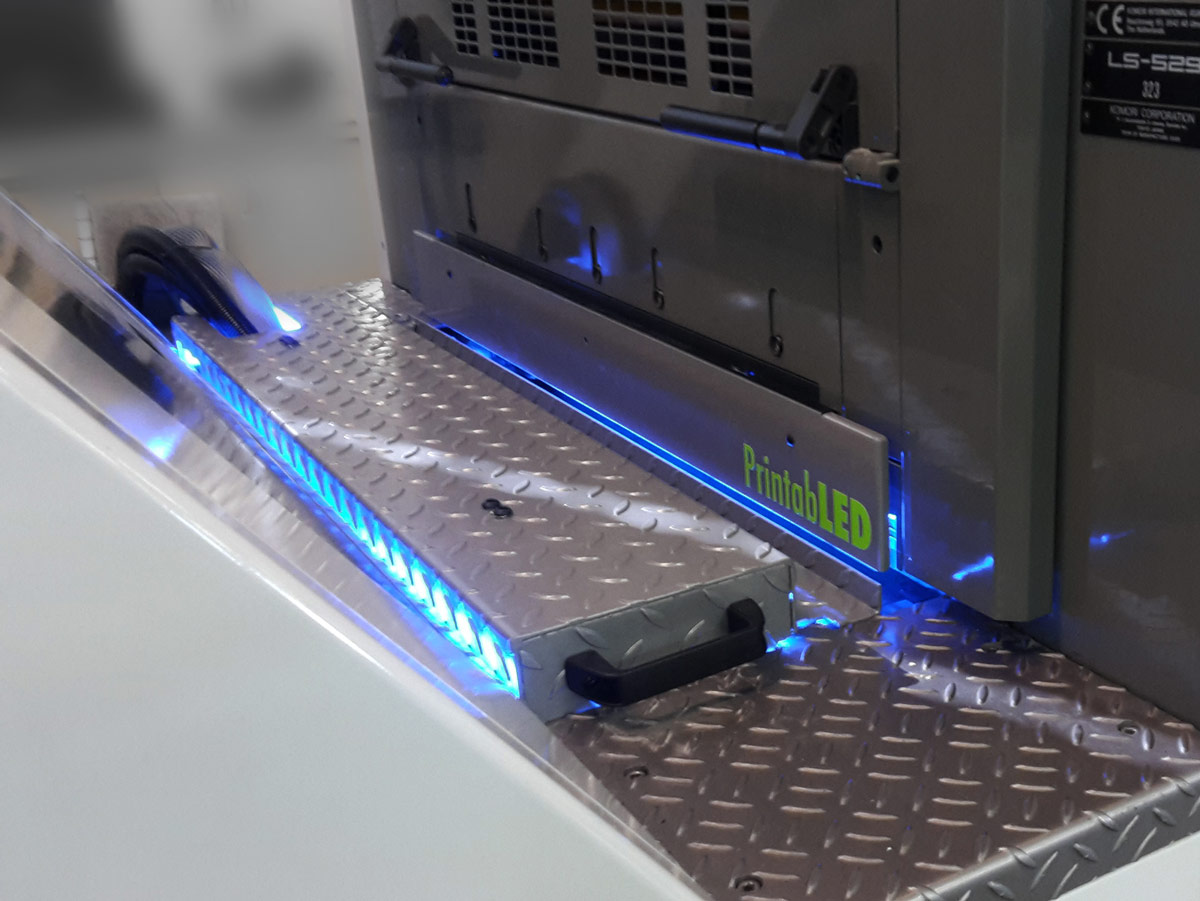

PrintabLED’s twin spirit of experience and innovation is the perfect combination to support customers by studying and analyzing every market requirement to design customized solutions.

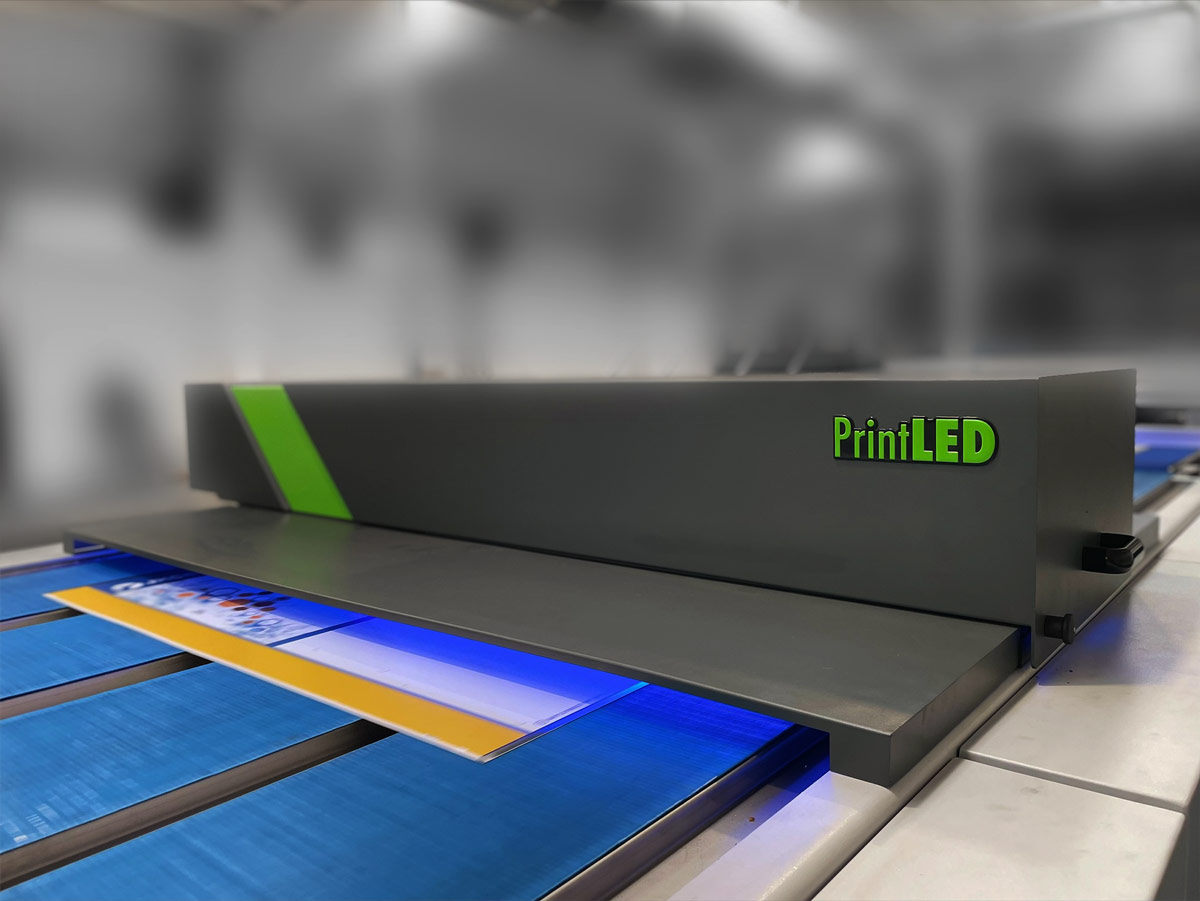

PrintLED’s UV LED systems are easy to install and the downtime of the press is minimal, thanks to the high engineering of the products and the team’s proven expertise.

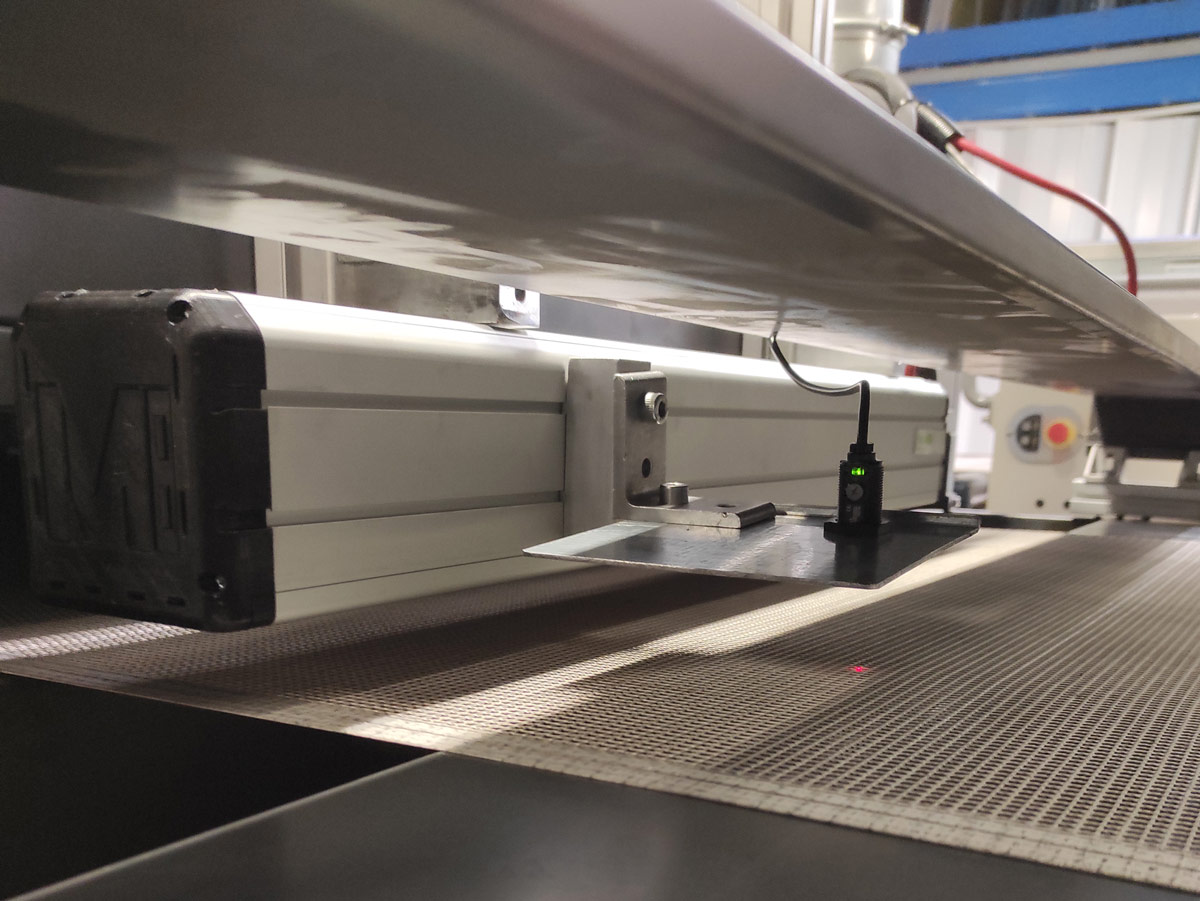

Technologies, engineering capabilities, and regulatory requirements evolve all the time and there are many ways to bring the performance of aged presses more to date with current standards. We continually develop and integrate UV LED technology to economically increase equipment productivity with lowest possible energy consumptions.

No. The surface temperature of LED UV lamps is about 50°C to 60°C (122-140°F), whereas mercury lamps have surface temperatures exceeding 398°C (750°F). The low operating temperature of PrintLED UV LED prevents damage to substrates and printing machines, requires less energy and is safer for the operators.

YES, PrintLED UV LED solutions are sustainable.

LED UV lamps utilize specially formulated adhesives and inks devoid of solvents, eliminating the release of volatile organic compounds (VOCs) and reducing their environmental impact. This approach also minimizes material usage and waste generation. PrintLED UV LED do not produce ozone and use mercury-free LED, eliminating the hazards associated with handling and disposing of mercury arc bulbs.

The absence of heat, ozone, and mercury in press rooms enhances safety, eliminates the expenses associated with cooling air blowers and ozone extraction systems, while also reducing ambient noise and odor, thereby improving the working environment.

Lastly, PrintLED UV LED consumes up to 80% less energy compared to traditional systems.

PrintLED is a trade mark of PrintabLED srl

Operational Headquarter:

Via L. Longo, 13-13A – 42021 Bibbiano (RE) Italy

Registered office:

Via E. Torricelli, 16/18/20 – 42027 Montecchio E. (RE) Italy

VAT: IT02487940351

REA: RE-286023

PEC: printabledsrl@legalmail.it